Why PE makes good pipelines

Learn why PE is such an incredible material

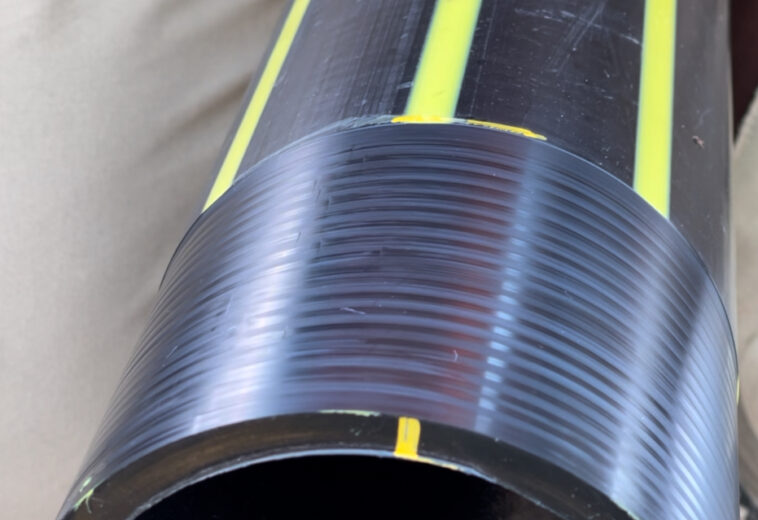

HDPE (High-Density Polyethylene) pipe is commonly used in Australian pipeline projects because it performs exceptionally well in harsh, varied conditions while remaining cost-effective and reliable over the long term. Australia’s climate, soil types, and vast infrastructure networks demand materials that can handle movement, pressure, and corrosion – and HDPE consistently delivers.

One of the key reasons HDPE is so widely adopted is its durability and flexibility. It can absorb ground movement caused by reactive soils, settlement, or temperature changes without cracking or failing, making it ideal for both urban and regional installations. Unlike steel or concrete, HDPE does not corrode, rust, or scale, which is especially important in aggressive soils and coastal environments common across Australia.

HDPE is also favoured for its leak-free jointing systems, particularly electrofusion and butt welding, which create continuous, fully fused pipelines. This greatly reduces water and gas losses, maintenance costs, and the risk of contamination. Its lightweight nature makes transport and installation easier and safer, lowering construction time and labour costs – an important advantage on remote or large-scale projects.

Finally, HDPE offers excellent long-term value and sustainability. It has a design life of 50 to 100 years, requires minimal maintenance, and is recyclable. Combined with its strong performance under pressure and proven compliance with Australian Standards, HDPE has become the material of choice for water, gas, sewer, and industrial pipelines across the country.

Installers working on PE pipelines in Australia must be PMBWELD301E or PMBWELD302E accredited. This is to ensure our gas and water infrastructure is safe, reliable and long-lasting. Interested in finding out how to become accredited? Talk to Lernna today.

- 1,358 views