INDUSTRY News

Follow Lernna to keep up-to-date with happenings in the industry

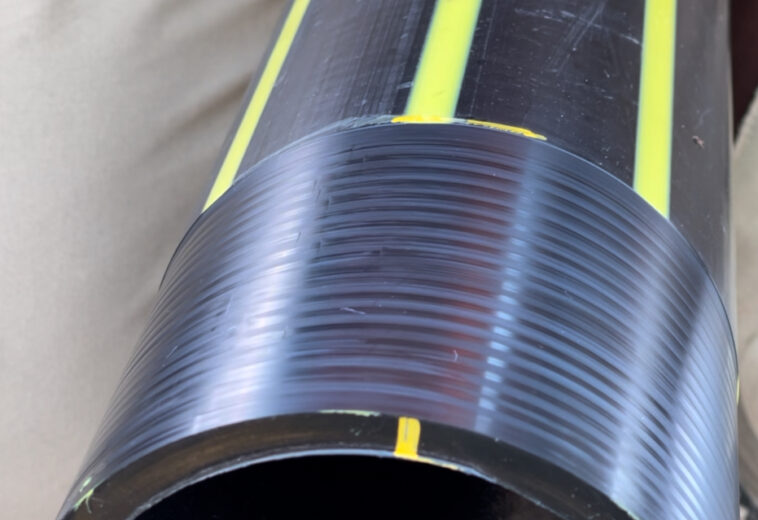

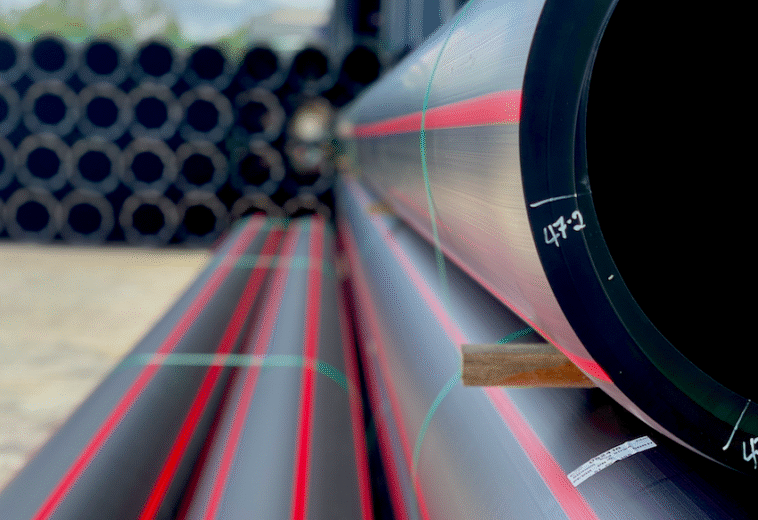

Why PE makes good pipelines

Learn why PE is such an incredible material

HDPE (High-Density Polyethylene) pipe is commonly used in Australian pipeline projects because it performs exceptionally well in harsh, varied conditions while remaining cost-effective and reliable over the long term. Australia’s climate, soil types, and vast infrastructure networks demand materials that can handle movement, pressure, and corrosion – and HDPE consistently delivers. One of the..

Read more- 1,358 views

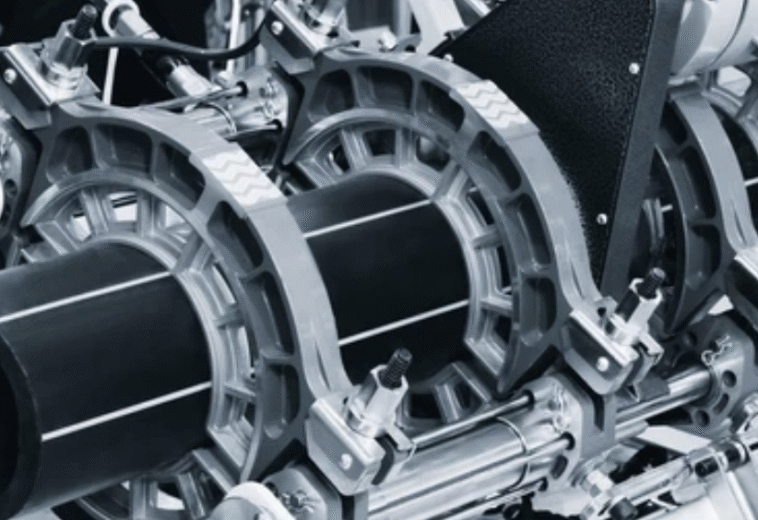

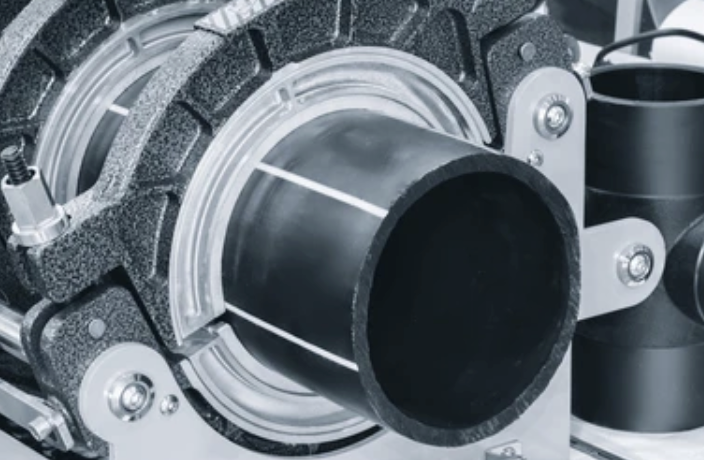

How does electrofusion work?

Joining PE pipe with electrofusion

Electrofusion is a method of permanently joining plastic pipes - most commonly polyethylene (PE) pipes - using heat generated through an electrical current. It’s widely used in water, gas and infrastructure pipelines as it creates strong, reliable and leak-free joints. The process uses specialised electrofusion couplers or fittings. Inside the fitting are embedded electrical heating.. Read more- 948 views

How Cost-Effective Are HDPE Pipelines?

Cost-Effective Pipelines

When it comes to pipeline construction, affordability isn’t just about the upfront price of materials – it’s about how long the asset lasts and what it costs to own over decades. This is where HDPE (polyethylene) pipelines consistently outperform traditional materials like concrete, PVC and ductile iron. PE pipelines are often more cost-effective to..

Read more- 967 views