Electrofusion training for plumbers

THE UPSIDE OF UPSKILLING

Why plumbers need electrofusion training Electrofusion (often called EF) is a trusted way to join PE pipe when butt fusion isn’t practical for example, when adding valves, elbows or tees, or when working in tight spaces where moving pipe just isn’t an option. Because electrofusion joints are permanent and often used in critical assets (gas,..

Read more- 34 views

- 0 Comment

Why polyethylene is trusted to deliver Australia’s water

85% OF OUR WATER IS PIPED THROUGH POLYETHYLENE

PE: DELIVERING THE FULL PACKAGE Polyethylene (PE) pipes have been around for more than 60 years. The first generation pipelines were modest performers. Fast forward to 2025 and PE now dominates the utilities space, accounting for around 85 per cent of water services infrastructure in Australian cities. You’ll also find it everywhere from telecommunications..

Read more- 25 views

- 0 Comment

Electrofusion Couses in Melbourne

So what is an electrofusion course and why should I do one? Electrofusion courses (Unit of Competency PMBWELD302E) teach you how to join polyethylene (PE) pipes using purpose-built electrofusion fittings that heat and fuse the pipe together from the inside out. It’s a proven, reliable method used every day on water, wastewater and gas jobs..

Read more- 21 views

- 0 Comment

How does electrofusion work?

Electrofusion: how it works Electrofusion (often called EF) is a trusted way to join PE pipe when butt fusion isn’t practical for example, when adding valves, elbows or tees, or when working in tight spaces where moving pipe just isn’t an option. Each electrofusion fitting has its own weld settings, such as fusion time,..

Read more- 19 views

Electrofusion training in Perth

So, what does an electrofusion course actually cover? An electrofusion welding course (Unit of Competency PMBWELD302E) teaches you how to join PE pipe using electrofusion fittings – the type with built-in heating wires that do the hard work of creating a permanent leak-free joint when set up properly. When it’s done right, electrofusion delivers strong,..

Read more- 18 views

- 0 Comment

Why peel pipe before electrofusion?

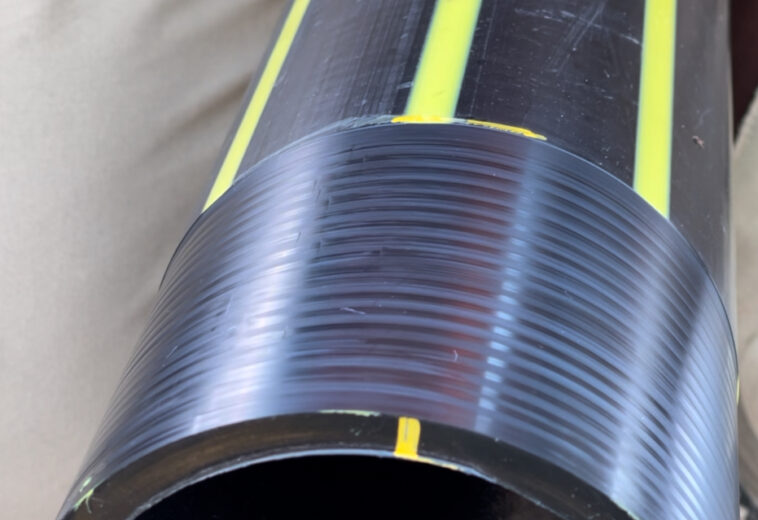

Why peel PE pipe? You need to peel PE pipe before electrofusion because the outer surface of the pipe is not weld-ready as it comes from the manufacturer, and leaving it untouched is one of the most common causes of electrofusion failures. Here’s why peeling matters: 1. Removing the oxidised layer PE pipe develops a..

Read more- 18 views

- 0 Comment

Electrofusion courses in Sydney

So what is an electrofusion course and what do they involve? Electrofusion welding courses (Unit of Competency PMBWELD302E) provide formal instruction in the joining of polyethylene (PE) pipelines using electrofusion fittings. The process uses fittings with special wires embedded inside them to deliver consistent, high-integrity joints. Completion of PMBWELD302E is a regulatory requirement for personnel..

Read more- 21 views

- 0 Comment

Why irrigation installers need electrofusion training

THE BENEFITS OF UPSKILLING

Why irrigation installers need electrofusion training Electrofusion (often called EF) is a trusted way to join PE pipe when butt fusion isn’t practical for example, when adding valves, elbows or tees, or when working in tight spaces where moving pipe just isn’t an option. Because electrofusion joints are permanent and often used in critical assets..

Read more- 14 views

- 0 Comment

Electrofusion Training in Brisbane

So what is electrofusion and how do you train to become an installer? Electrofusion courses, which are also known by the Unit of Competency Code PMBWELD302E, and they teach you to join polythylene (PE) plastic pipes using heating elements which are embedded into special electrofusion fittings. Completing a PMBWELD302E course is mandated for those using..

Read more- 37 views

- 0 Comment

Why PE makes good pipelines

Learn why PE is such an incredible material

HDPE (High-Density Polyethylene) pipe is commonly used in Australian pipeline projects because it performs exceptionally well in harsh, varied conditions while remaining cost-effective and reliable over the long term. Australia’s climate, soil types, and vast infrastructure networks demand materials that can handle movement, pressure, and corrosion – and HDPE consistently delivers. One of the..

Read more- 1,358 views

Leave a Reply