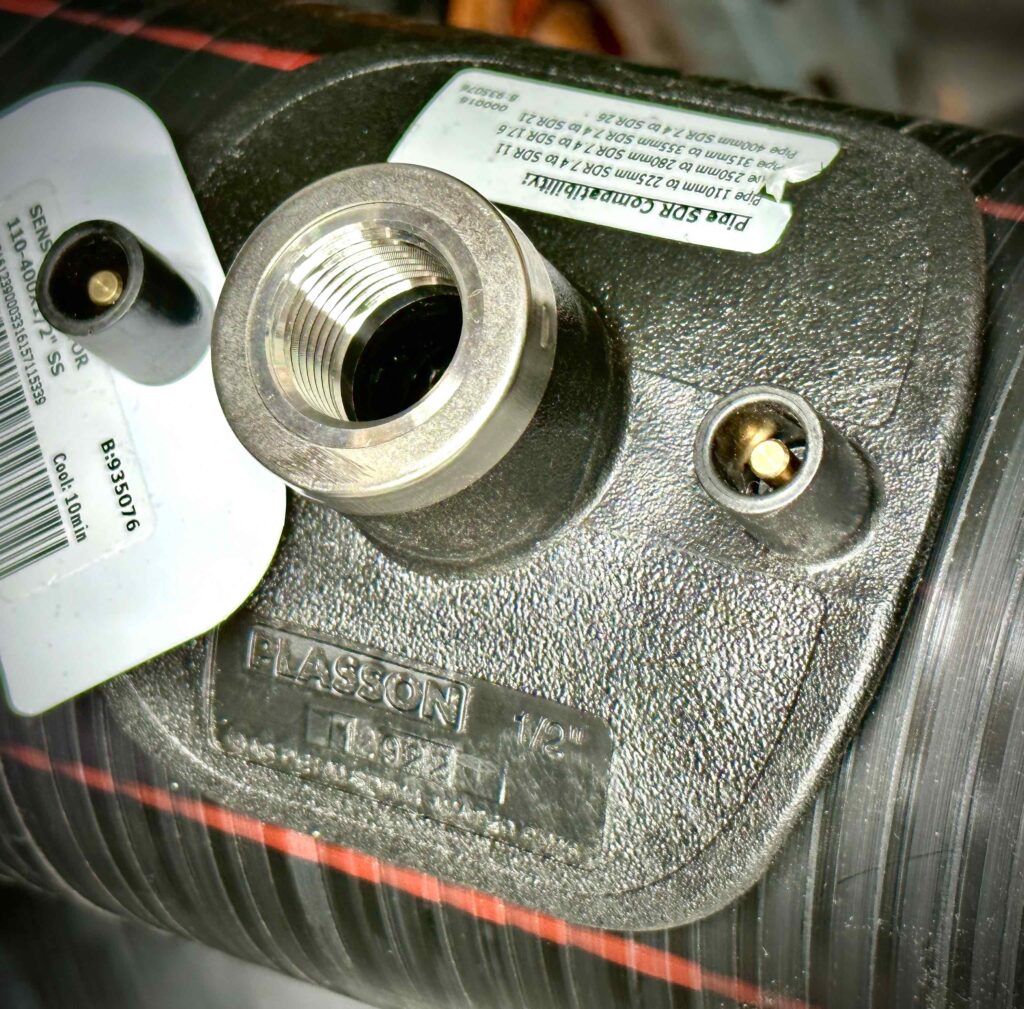

Electrofusion fittings are used in water supply lines and gas pipelines. Fittings are available in different sizes and configurations and are designed to create a strong joint in pipelines that carry fluid under pressure.

The electrofusion fittings get their name from the heat treatment technique used in installation. Electric current is applied to special wires embedded in the fittings to produce heat. The heating technique is safe and delivers fast results.

Key Benefits of Electrofusion Fittings

The key benefits are strong joints, cost-effective solutions, long-lasting results and easy installations. Learn about the benefits of electrofusion and the range of fittings and solutions offered by this method of joining polyethylene pipes. Here are some key points on electrofusion and the solutions and benefits they offer joining polyethylene:

Strong Joints

Electrofusion fittings are strong yet light-weight and easy to handle. Quality fittings feature fusion zones and long penetration depths to ensure strong joints. Using quality fittings according to manufacturer’s directions delivers durable and robust joints resulting in pipelines that last for many, many decades.

Cost-effective

Being made of robust and light-weight plastic makes electrofusion fittings cost-effective and preferable for many jobs. The fittings do not require the same equipment for transportation and handling as other materials, like iron and concrete.

Improved Performance

Electrofusion fittings are manufactured to strict safety standards and deliver full pressure ratings for different applications.

Non-Toxic

Unlike some pipeline systems, electrofusion fittings are both non-corrosive and non-toxic. They are resistant to most chemicals including many aggressive chemicals used in industrial applications. Impact and pressure resistance are also added advantages of polyethylene pipelines joined by electrofusion.

Low Installation Costs

These fittings can only be installed by those certified in Electrofusion Welding (PMBWeld302) but installation is straight forward and less time-consuming than many other systems.

Durable

Electrofusion fittings are known for their durability. They can last for over 100 years with minimal maintenance. These installations are also easy and relatively low cost to repair.

In addition to the above, the electrofusion fittings are immune to corrosion. They are highly resistant to environmental stresses and earthquakes. Also, they are flexible and lightweight. Both features will help with fast and flawless installation.

Electrofusion Fitting Applications

Electrofusion fittings are used in natural gas distribution and have also passed early tests for use in hydrogen pipelines. They create a strong joint and ensure safe flow. There is a range of fittings to help make different types of connections including offtakes, installation of meters and connections to other equipment.

Electrofusion fittings are also suitable for industrial systems and for fire protection, mining, oil, water, waste water and even landfill.

Electrofusion Installation

All electrofusion welding must be carried out by certified installers. Fuserite offers certification in Electrofusion PMBWeld302 and also refresher courses for those looking to renew their certification.

All Fuserite courses offer a mix of online learning and hands-on training. Take a look at the range of courses on offer to help you upskill and expand your business today.