Why peel pipe before electrofusion?

Why peel PE pipe?

You need to peel PE pipe before electrofusion because the outer surface of the pipe is not weld-ready as it comes from the manufacturer, and leaving it untouched is one of the most common causes of electrofusion failures.

Here’s why peeling matters:

1. Removing the oxidised layer

PE pipe develops a thin oxidised “skin” during manufacture, storage and exposure to air and UV. This layer won’t fuse properly. Peeling removes it and exposes clean, virgin material that will melt and bond as intended.

2. Eliminating contamination

Dirt, dust, moisture, sunscreen, grease and even fingerprints can stop proper fusion. Peeling physically removes any contamination from the fusion zone instead of just spreading it around with cleaning wipes.

3. Ensures proper melt and mixing

Electrofusion relies on the surface plastic of the pipe and fitting melting, flowing together and mixing completely under pressure. If the pipe surface isn’t peeled evenly, the melt won’t mix correctly, leading to weak or incomplete joints.

4. Creates a consistent fusion surface

Mechanical peeling gives a uniform surface thickness across the fusion zone. This helps the fitting heat evenly and build the correct melt pressure inside the coupler.

5. Supports compliance and traceability

Correct pipe preparation is a requirement under manufacturer instructions, Australian Standards and PMBWELD302E. Skipping or poorly doing this step can make the joint non-compliant, even if it looks fine from the outside.

Bottom line:

If you don’t peel the pipe, the fitting is trying to weld to an oxidised, contaminated surface and the result will a weak weld. The joint might hold pressure at first, but it’s far more likely to fail over time.

That’s why proper, mechnical peeling immediately before welding is non-negotiable for quality electrofusion work.

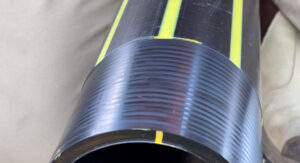

How to Check It’s Been Properly Done

A properly peeled pipe should have:

- A uniform, matte finish (not shiny)

- No glossy patches or streaks

- Even scraping all the way around the pipe

Once assembled:

- The pipe should reach the insertion depth mark

- If you can see unpeeled pipe inside the fusion zone, the joint is non-compliant.

Peeling must be done immediately before assembly.

- If the pipe sits around scraped for too long, oxidation and contamination start again

- If in doubt, re-peel

Peeling Issues That Lead to Weld Failures

❌ Hand Scraping or Sanding

- Inconsistent depth

- Missed oxidised material

- Creates grooves instead of a clean surface

👉 Always use a mechanical pipe peeler designed for PE.

❌ Incomplete Peel

- Peeling too short of the insertion depth

- Missing sections around the circumference

👉 This leads to partial fusion – one of the hardest failures to detect visually.

❌ Touching the Peeled Surface

Bare hands leave oils and contamination.

👉 Once peeled, don’t touch it. If you do you must re-peel.

❌ Letting the Pipe Sit Too Long

Peeled pipe left exposed:

- Re-oxidises

- Collects dust and moisture

👉 If there’s a delay, peel again.

❌ Over-Peeling or Gouging

- Removes too much material

- Weakens the pipe wall

- Creates uneven heating zones

👉 Peeling should be controlled and even, not aggressive.

The Big Picture

Electrofusion is unforgiving when it comes to preparation.

Most EF failures traced back in investigations come down to poor or incomplete peeling – not the fitting, not the machine.

If the pipe isn’t prepared properly, the weld never had a chance.

Lernna is a specialist Registered Training Organisation focused solely on electrofusion and butt welding across Australia. Our goal is simple: lift standards, lock in best practice, and make sure the people building and maintaining critical pipeline infrastructure are trained to do the job properly – every time.

We work closely with industry to deliver training that’s practical, compliant and aligned with Australian Standards, current technology and real-world conditions. With experienced trainers, straight-talk instruction and a strong safety focus, we help tradespeople build skills they can trust on site and assets that last long term.

Curious? Take a look at the courses we offer.

- 19 views

- 0 Comment