Keys to Successful PE Welding

To ensure a successful electrofusion, the key steps involve thorough preparation, precise alignment, accurate fusion, and proper cooling. This includes cleaning and preparing the pipe and fitting surfaces, ensuring proper alignment and clamping, executing the fusion process according to the manufacturer’s instructions, and allowing sufficient cooling time before removing the clamps.

Plasson fittings come in a protective plastic bag. keep packaged fittings stored out of direct sunlight until use.

use the plastic to hold the fitting during installation

Key Installation Tips

- Once surfaces are peeled for welding, avoid any possible re-contamination of the prepared surfaces by equipment, hands and clothing.

- Use a shelter in wet/windy conditions to avoid water/dust contamination.

- Hands must be regularly cleaned with wipes to avoid contamination or wear disposable gloves.

- Ensure the peeled pipe and the inside of the fitting are thoroughly cleaned with Plasson Pipewipes and allow moisture to flash off before welding.

KEEP WELDING TERMINALS CLEAN

NEVER DROP WELD TIPS IN THE DIRT

THE BASICS OF THE ELECTROFUSION WELDING PROCESS

• Clean pipes

• Peel pipes

• Wipe pipes

• Clamp pipes and fitting

• Weld

• Cool in clamped position

IN ALL CASES:

• All installers must be qualified and trained in Electrofusion welding procedures.

• Follow PIPA Industry Best Practice Guidlines, POP001.

CAUTION

Electrofusion should only be done in a gas-free environment and away from any flammable materials. Plasson Weld Control Boxes are an electronic device. If users choose to use Plasson Electrofusion equipment in a gaseous environment, they do so at their own risk.

A 15A Earth pin is fitted to all plugs. If used with other fittings, check with fittings supplied for earth

requirements – the power consumption of the fitting should not exceed 2400w

(eg; 60 amps @ 40V output).

attention to detail

- The electrofusion process must be carried out as one continuous process from pipe surface preparation to fitting cooling stage.

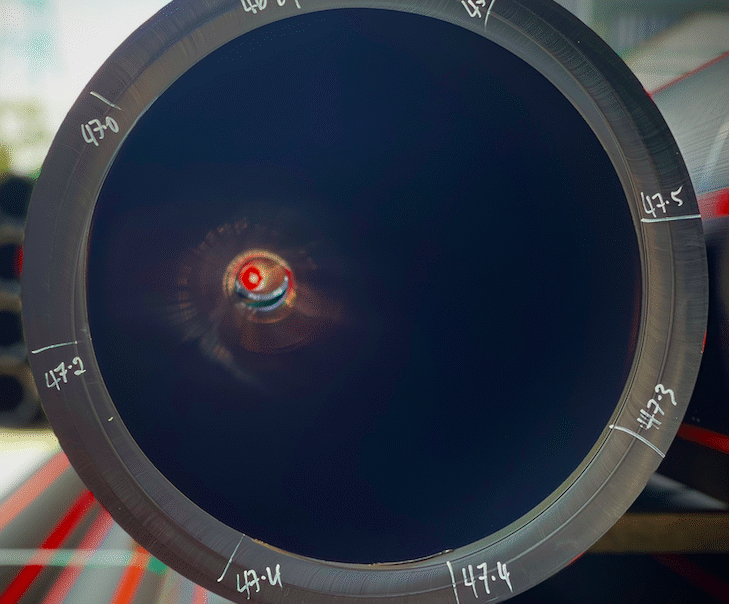

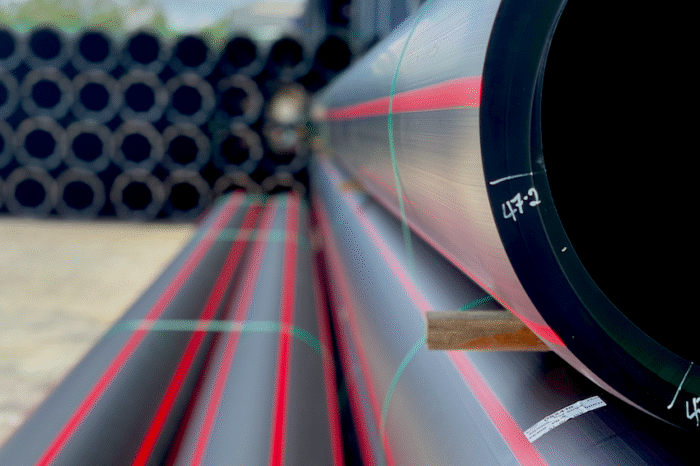

- Where there is evidence of pipe ovality, the pipe must be re-rounded using industry approved equipment. Greater levels of ovality are found in coiled pipes, in pipes with higher SDRs and in diameters above 400mm.

- The electrofusion equipment must be compatible, calibrated and capable of providing the correct fusion voltage for the full duration of the electrofusion cycle.

- Alignment clamps must be used to ensure there is no movement between the pipe and fitting during the fusion and cooling processes.

- For large diameter couplers, combined hydraulic re-rounding and alignment clamps should be used.

- For saddle fittings a top loading clamp is required. It should be calibrated and capable of applying the correct clamping force.

Quality assessment

• Following the electrofusion process, the fitting should be inspected to ensure that the fusion indicator(s) is (are) raised. The fusion indicator identifies that the electrofusion process has taken place. It is not confirmation of a quality joint

• For a good quality joint, there should be no visible melted material beyond the fitting’s edges

• At the end of the electrofusion cycle, the control box should be checked to confirm that the cycle has completed without error

• The fusion joint record data should be retrievable for quality inspection or joint investigation

• Each joint should be marked with the joint reference details

• Follow industry approved pressure test procedures before commissioning the joint

best practice

The best tip to achieving good EF welds is summed up in two simple

words: “precision” and “accuracy”.

Whether you are installing a 16mm coupler or a 1000mm fitting, precision and accuracy is crucial at every step of the process. A good weld is about following recommended Best Practice, having precisely the right tools to do the job and taking the time to use them accurately.