Why Use Electrofusion Instead of Butt Welding?

Electrofusion and butt welding are both methods for joining thermoplastic pipes, but they differ in their techniques and equipment. Electrofusion uses specialized fittings with embedded heating elements to melt the plastic, while butt welding involves heating and pressing the pipe ends together directly.

Electrofusion

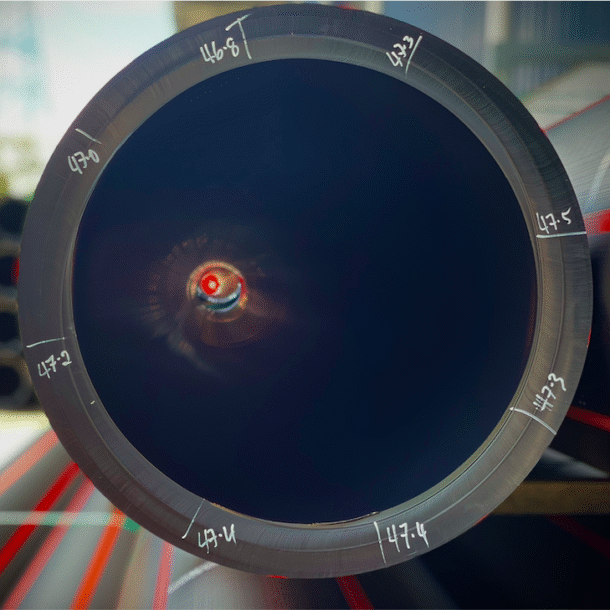

- ProcessElectrofusion involves placing a fitting with built-in electrical resistance coils around the pipe ends. An electric current is then passed through the coils, generating heat that melts the plastic and fuses the fitting to the pipe.

- EquipmentRequires electrofusion fittings and a welding machine that provides the electrical current.

- ApplicationsSuitable for a wide range of pipe sizes, including smaller diameters and situations where access is limited.

Butt Welding

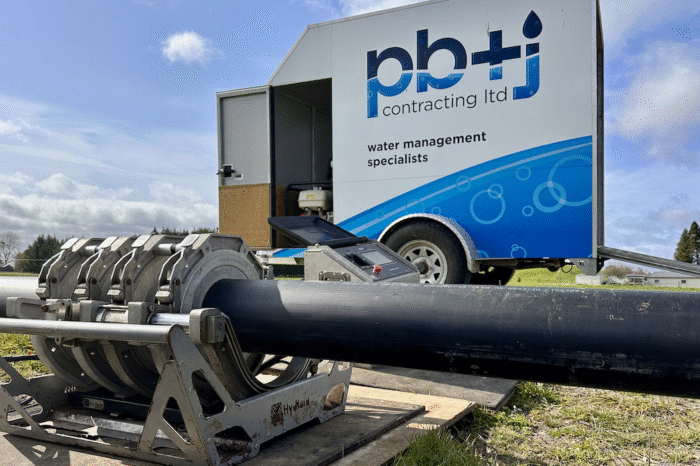

- ProcessButt welding melts the ends of the pipes directly using a heated plate. The molten pipe ends are then pressed together under pressure to create a strong bond.

- EquipmentRequires a specialized butt fusion machine that can heat and align the pipe ends.

- ApplicationsGenerally used for larger diameter pipes and situations where a strong, seamless joint is required.

which is best?

- Joint Formation

Electrofusion creates a joint using a separate fitting, while butt welding fuses the pipe ends directly.

- Equipment Complexity

Butt welding typically requires more specialized and potentially larger equipment than electrofusion.

- Accessibility

Electrofusion is often preferred in tight spaces or where access is restricted, while butt welding may require more open space for the equipment.

- Cost

Butt welding can be more economical for large projects due to the lack of fittings, while electrofusion can be more cost-effective for smaller projects or when fittings are required.

Why should you care about the difference?

- Project Requirements: Depending on your project’s specifications, such as pipe diameter, material compatibility, joint configuration, and welding speed, you may choose either electrofusion or butt fusion.

- Cost Considerations: Consider the initial equipment investment, ongoing maintenance costs, and labor requirements associated with each welding method.

- Quality and Reliability: Both methods can produce strong and durable fusion joints when performed correctly. However, factors like operator skill, welding conditions, and environmental factors can affect joint integrity.

- Efficiency and Productivity: Evaluate the efficiency and productivity of each method based on your project’s timeline, labor availability, and desired welding speed.

- Compatibility: Some fittings and pipe configurations may be more compatible with either electrofusion or butt fusion, so consider the availability of compatible components for your specific needs.

Ultimately, the choice between electrofusion and butt fusion depends on various factors specific to your project, including technical requirements, budget constraints, and logistical considerations. Consulting with experienced welding professionals or engineers can help you make an informed decision.

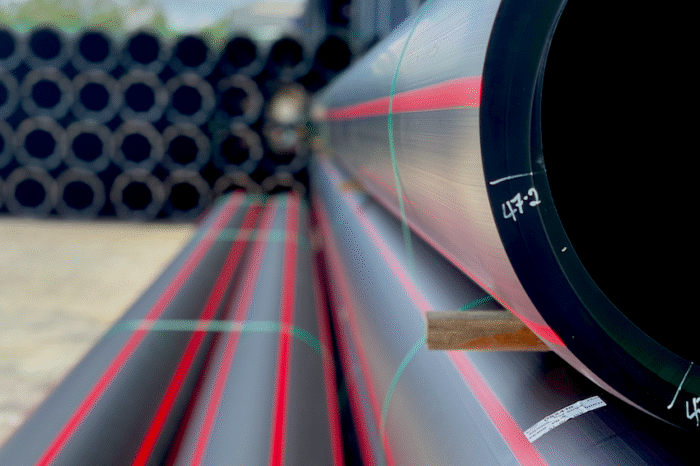

pe100

Which ever jointing method is used, PE (Polyethylene) pipelines are an excellent choice due for sustainable, long-life pipelines due to their durability, flexibility, and resistance to corrosion and chemicals. These characteristics translate to long-term cost savings and reliable performance in various applications, including water distribution, natural gas transportation, and sewage systems