Three Things To Watch With PE Pipe

The Pitfalls Of Reversion, Ovality and flat spots

Pipe surface temperatures can be much higher than the ambient temperature and reach as high as 70°C.

Electrofusion welding machines have upper and lower temperature operating limits of -10°C to 45°C.

Pipe end reversion

PE pipes often exhibit circumferential reversion (also known as toe-in) at pipe ends which can cause reduction of the pipe OD. Reversion can occur due to the residual stress introduced during the manufacturing process.

Reversion can create excessive gaps between the pipe and fitting surfaces, which can compromise weld integrity. The following calculation determines if the reverted pipe end can be welded:

→ Prior to peeling, measure the distance equivalent to DN x 5% from the pipe end. At this position, the pipe OD must be no smaller than the DN.

→ Place a straight edge, such as a spirit level or ruler, on the pipe end. If reversion is present, cut the pipe end at the position where the pipe end begins to toe-in.

For example, when checking reversion on a DN500 pipe end:

1. 500mm x 0.05 =25 mm. Measure 25 mm back from the pipe end.

2. 25 mm from the pipe end, the pipe OD should be no smaller than 500 mm.

3. If the OD is less than 500 mm, cut the pipe squarely at that position.

Freshly cut pipe can revert again. To avoid the risk of recurrent reversion complete electrofusion jointing as soon as the pipe has been prepared.

Ovality

Pipe ovality (out of roundness) and flat spots can develop during manufacture, coiling or storage and handling. Ovality creates an uneven annular gap between the pipe and the fitting, which can comprise the weld integrity.

Some pipes may be too oval to fit into electrofusion sockets or exceed the ovality tolerance for saddle-type fittings. Re-rounding tools can be used to correct ovality, reducing the uneven annular gap between the pipe and fitting surfaces in the fusion zone. Re-rounding tools must remain in place during the welding and cooling phases.

Pipe can also have one or several flat spots on the outer surface. Flat spots and cause difficulty peeling the oxidised material from the pipe surface and create excessive localised annular gaps between the pipe and fitting. Re-rounding tools may be unable to correct flat spots.

Re-Rounding

Where pipe cannot be re-rounded within the acceptance criteria, other methods may be applied such as:

→ Trimming back the end of the pipe until the flat spot is removed.

→ Relocating a saddle to an alternative position or rotating the pipe.

→ Butt-welding pipe tails to allow compliance with the acceptance

criteria.

FLAT SPOTS

Following pipe-re-rounding, accurately measure the flat post depth using a pipe ovality

gauge, intersected with a steel ruler.

Flat spots can create excessive localised annular gaps between the pipe and EF fitting. This gap

can be tolerated up to a certain limit.

visual inspection

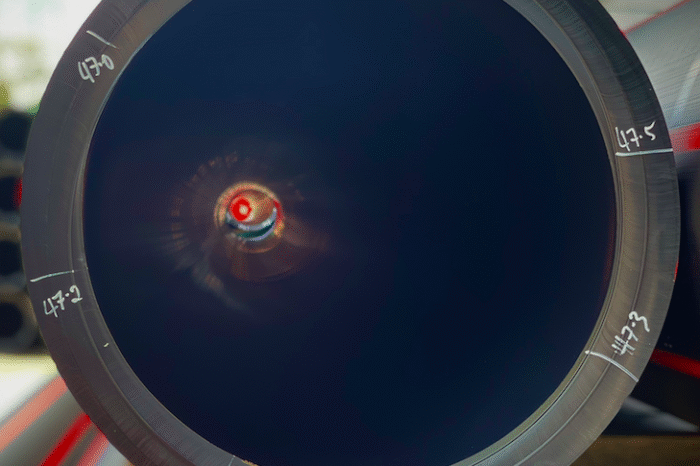

After peeling, visually inspect the pipe surface for any remaining scores or deep gouges. Any surface

irregularities can cause problems in the fusion zone, resulting in incomplete welds, or formation of voids.

If scores or gouges remain on the surface, peel the pipe a second time to remove. If the scores or gouges cannot be removed by peeling, cut the damaged section of pipe out.

Weld Data

It’s important for the installer to record information for each weld to demonstrate the joint was prepared by a qualified welder and following industry best practice.

The minimum recording requirements and traceability for a weld record include project, welder, equipment, pipe, fitting and installation information. It should be noted the asset owner may require additional information to be recorded.

In addition to quality control records a field fusion quality assurance plan which details the inspection and test

requirements for electrofusion welds in the project may be required. Refer to Appendix B for more information.

data capture

There are a variety of digital tools and apps available to capture electrofusion welding data including

photographs and geolocation capability. These tools simplify the task of capturing the welding process and

traceability information. These apps are supplied by electrofusion fitting manufacturers and are valuable

QA tools.

Electrofusion welding machines can offer wireless connectivity, collecting welding data captured during the

fusion process. Electronic data is stored and typically downloaded via a mobile phone app to the cloud for

immediate storage or future retrieval by interested parties e.g., asset owners, consultants, contractors.

sustainability

Sustainability and plastic are not the most comfortable of bed fellows but the most sustainable pipeline is one that lasts and doesn’t leak. With the right tooling and technique, electrofusion joints will remain leak-free for at least 50 years and many will last over 100.